Vision Inspection Machine: The Best Solution for Pharmaceutical Industry You Can’t Miss

It is a worldwide acknowledged fact that the quality control of drugs and medicines,

together with their packaging, are essential measures to decrease the risks of

defective

products. Meanwhile, these effective measures can optimize the packaging process

with

automatic methods to help pharmaceutical companies reduce operating costs. In this

condition, vision inspection

machines

are

becoming helpful and essential pharmaceutical solutions to guarantee accurate

inspections on the production line.

For instance, COVID-19 vaccines and nucleic

acid detection with intact packaging are indispensable in coronavirus to ensure

high-performance detection efficiency. However, one fact should always be addressed

vision inspection machines play pivotal roles in packaging these important

pandemic-related tools to ensure their superior efficiency.

This article will guide you through major things about vision inspection

machines

and other pharmaceutical packaging machines.

Current Requirements towards Vision Inspection Machines

Vision inspection machines are automated tools used to inspect the condition of drugs with lenses and optics. The use of this advanced machine can help eliminate the manual tasks associated with inspecting a variety of different drugs. Therefore, the ever-changing society puts forward higher demands in vision inspection machines, which include:

High Accuracy

Accuracy is basic and essential for producing accurate images, which in turn helps improve quality and reduce defects. In order to achieve high accuracy, vision inspection machines typically use several different techniques, such as sensors and cameras. For instance, the automatic inspection machine LFIM-48 from Pharmapack is equipped with highly sensitive sensors and various clear cameras to ensure high accuracy. On the one hand, sensors are not only used to measure the distance between the drug being inspected but also promote the smooth operation of the vision inspection machines. On the other hand, cameras are responsible for capturing images of objects to check whether they are undamaged. By using these two measurements, the accuracy of the image can be determined.

Fast Speed

There is a growing demand for fast-speed vision inspection machines as the industry moves faster and needs more accurate quality control. Unfortunately, the traditional inspection process by humans often takes days to detect the same amount of drugs, which can be a bottleneck in the production process. Pharmapack gets insight into the market and updates various inspection systems and machines, such as LFIM-72 and LFIM-48. For instance, the vision inspection machine LFIM-48 detects 400 bottles per minute. On the other hand, LFIM-72 is an automatic inspection machine designed to detect oral liquid meters, and it has a stable speed of 600 bottles per minute. To conclude, by speeding up the inspection process, manufacturers can reduce the time it takes to inspect products. In addition, faster inspection speeds can help save on production costs due to reduced labor and processing time.

Low Cost

Vision inspection machines are cost-effective for a pharmaceutical packaging company as they help in reducing the time and workforce needed for inspecting drugs. Machines can inspect products quickly and accurately, which helps to reduce quality issues. Additionally, vision inspection machines can be used in safety-critical applications with less money, making the overall investment more cost-effective.

Other Major Pharmaceutical Packaging Machines You Should Know

Except for the vision inspection machines mentioned above, a variety of pharmaceutical packaging machines available on the market meet different needs. Below are three must-have machines that are used for fast and qualified packaging:

Bottle Labeling Machines

Bottle labeling machines are increasingly in demand by the beverage industry as they can quickly and accurately label millions of bottles per hour. For instance, our bottle labeling machines are easy to use so that even inexperienced operators can get started quickly. Moreover, they are affordable, and businesses can invest in them without worrying about long-term costs.

Counting Machine

Pharmaceutical counting machines are used in many different industries to help with the accuracy and speed of counting drugs. These machines have been designed to count pills, tablets, and other pharmaceutical products.

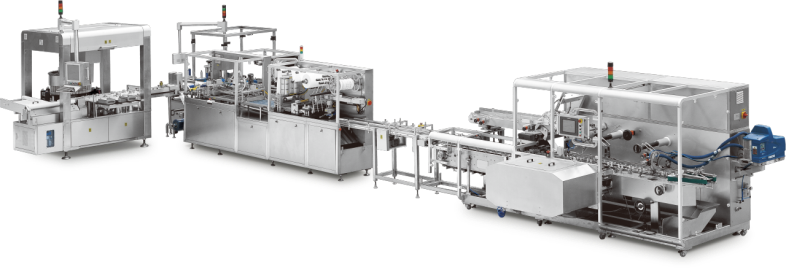

Antigen Test Kit Packing Machine

The antigen test kit packing machine is designed to help pack antigen test kits. It can not only automatically assemble the diagnostic cassette by putting the cassette and desiccant into a bag but also ensure proper and neat packaging of antigen test kits.