2022 the Most Acclaimed Inspection Machine You Can’t Miss!

The advancement of technology has witnessed that inspection is becoming indispensable and plays a vital role in the pharmaceutical inspection processes. Before the advent of inspection machines, manual inspection used to be the major way to accomplish the inspection procedure. However, one of the major unstable factors, human efficiency, presented by the manual inspection method, will bring numerous bad effects to pharmaceutical industries and potential buyers.

(Copyright photo from https://unsplash.com/photos/FsVEqeiOtPo)

Thus, in order to prevent medication accidents and supervise the safety of liquid medicine, including the coronavirus vaccine that is essential nowadays, the automatic inspection machine comes in with countless benefits. For instance, it can ensure efficiency, accuracy, and stability in the inspection process, which can be achieved with the help of vision inspection technology, analysis systems, and other systems.

Suppose you are in the market to find the best vision machine to boost production efficiency and enhance brand competitiveness. In that case, this article will recommend the most acclaimed ampoule inspection machine that will fulfill your specific needs.

5 Reasons to Buy LFIM-72 Inspection Machine

It is a well-known fact that an inspection machine can be used for liquid inspection, syringe inspection, etc. However, since it is a troublesome issue to pick out the best inspection machine among various choices, we at Pharmapack want to recommend one of the most popular inspection and vision machines which are produced to ease your user experience.

The following are some top-tier merits of our LFIM-72 continuous inspection machine.

1. Automatic Control

With the support of advanced technology, the inspection machine is equipped with automatic controls, requiring less human resources to a large extent. For instance, the whole inspection process is under the construction of the electronic control system, achieving fully automatic operation.

On the one hand, during the inspection procedure, the inspection machine transports the detected bottles automatically from the vertical feeding platform, the bottle feeding star wheel, the main tower, and finally to the tray or on the slide. On the other hand, the syringe inspection machine will automatically screen out unqualified products, helping users save labor costs while creating more value.

2. Solid Components

To ensure product quality, we are always dedicated to using the most advanced and solid materials and components to produce the LFIM-72 inspection machine. Some of our major components are listed below:

ü The inspection machine uses stainless steel, which ensures the product becomes more durable in the long run.

ü The inspection components adopt imported top configuration. For instance, our servo drive system is the original imported product of ABB, a leading global technology company well-known for quality-assured products.

ü We also use high-quality electrical, electronic, and pneumatic components, such as Beckhoff’s PLC and industrial touch computers.

3. Advanced Image Processing Technology

The LFIM-72 inspection machine is equipped with 21 cameras, which are produced under the industry-leading parallel processing technology. It means that the back end of each camera is equipped with a set of high-speed DSP image processing systems independently developed by our professionals.

By using the up-to-grade image processing technology, our inspection machines get rid of the speed bottleneck of the traditional industrial computer serial processing system. In addition, these cameras guarantee the high-speed transmission of the data and fast data processing, allowing you to get the image captured by the camera immediately without missing.

4. Steady Working Speed

Steady working speed is a fundamental factor that an automatic vision inspection should have. Compared with inspection by a human whose eyes may not always be efficient in finding out all unqualified products, the automatic inspection machine improves the working efficiency.

In terms of the LFIM-72 vision machine, it is capable of detecting 10 ML oral liquids for 600 bottles per minute! Such an incredible working speed can not only ensure inspection stability but also increase the company’s efficiency.

5. Wide Detection Areas

As aforementioned, the equipment has 6 groups of inspection stations and 21 cameras. These cameras are adjustable, meaning you can adjust their positions, heights, and angles according to your needs. In this way, more detection areas are allowed and covered with adequate inspection cameras. Moreover, the product can be used to inspect more liquids and the body of the bottle.

You will be amazed by how many liquid solutions this machine can be applied to, from the ampoule, vial, oral liquid, and even coronavirus vaccine. In this case, an unqualified coronavirus vaccine can be easily detected with our machine. If you want to find a high-quality and accurate inspection machine to detect the coronavirus vaccine, our LFIM-72 inspection machine is the perfect option undoubtedly.

Top Reasons to Choose a Reliable Supplier: Pharmapack

We at Pharmapack are a reliable inspection machine provider worldwide, and our products are widely used worldwide and favored by users. We export our products to more than 50 countries annually. Moreover, we have carried out successful programs and won the trust of our clients, including Aurobindo, AstraZeneca, AD, Baiyunshan, and Baxter. The following are our strengths and abilities to attract potential buyers.

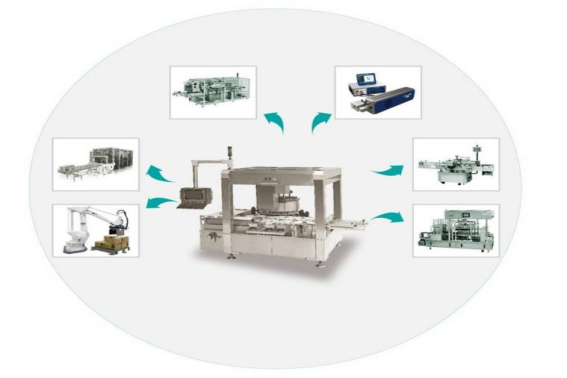

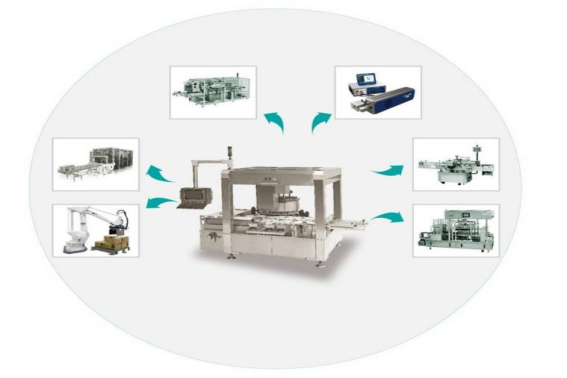

ü One-stop service system. We supply the most perfect "turnkey" packaging solutions for every customer, allowing them to experience the convenience of a one-stop solution.

ü Strict quality control. All of our machines endure tests by internationally certified companies and follow standards.

ü Perfect inspection equipment. To cater to our clients’ needs in a bulk quantity, we offer no less than 1000 production lines and more than 800 applications.

ü Experienced R&D group. We are equipped with more than 10 specialists and no less than 70 senior technical engineers to supply professional technical support for you.

ü Industry-leading Servo Control Technology. This technology is featured with self-detection and multiple modular designs so as to be geared to different needs.

ü Well-developed global marketing and service network. Our installed bases are located in more than 30 countries so that more clients can enjoy our service.

Set up in 2002, Pharmapack has been experienced in packaging machine manufacturing for 20 years. As a smart bottle packaging line manufacturer, we always make great endeavors to give turnkey packaging solutions to our customers. If you consider buying an inspection machine, an filling machine, a counting machine, or other machines related to packaging, we are always your reliable choice.