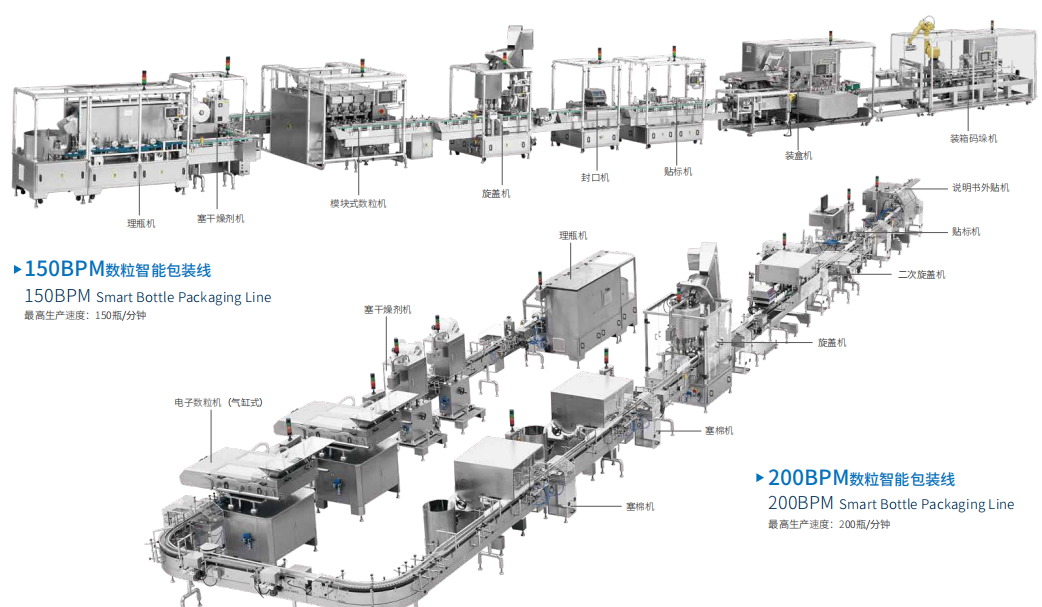

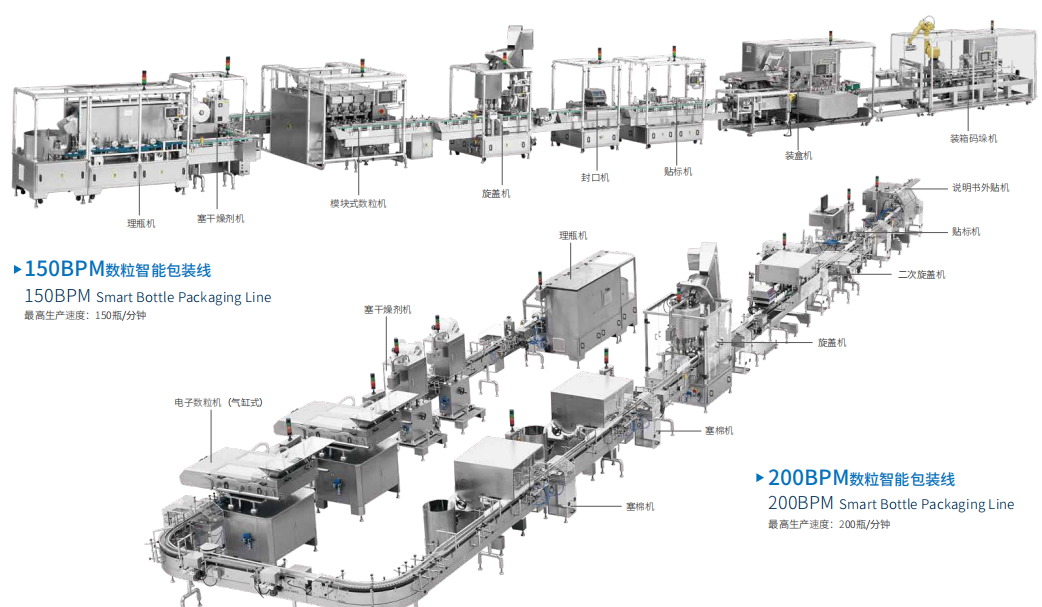

Smart Bottle Packaging Line:How to ensure the quality of drug packaging

The quality of pharmaceutical packaging is a very critical aspect of pharmaceutical production management, because if quality problems occur, they may have serious effects on the health of patients and even endanger human lives. Therefore, it is crucial for pharmaceutical companies to ensure the quality of drug packaging. As a modern production equipment, intelligent bottle production line plays an important role in ensuring the quality of pharmaceutical packaging. In this article, we will introduce how the intelligent bottling production line can guarantee the quality of pharmaceutical packaging from the following aspects.

I. Visual management of production process

The intelligent bottling line adopts digital control system to realize the visual management of the production process. The production line is equipped with various sensors, monitors and other devices, which can monitor the data in the production process in real time and feed them back to the control system. In this way, the management personnel of the enterprise can monitor and control the production process anytime and anywhere, make timely adjustments and improvements, and ensure the stability of the quality of drug packaging.

II. Precise measurement and filling

The quality of drug packaging must ensure the accurate ratio of drugs and the accurate volume of drugs in containers. The intelligent bottling production line is equipped with high-precision metering system and filling equipment, which makes the production line more accurate and stable compared with the traditional manual metering method. In addition, during the filling process, the drugs are connected to the bottles through aseptic pipes, which protects the drugs from bacteria and other contamination and ensures the purity and sterility of the drugs.

III. Automatic detection and quality control

The intelligent bottling line is equipped with high-precision measuring machines, and also has an automatic detection function for quality. This function performs an automatic test on each bottle after filling the medicine. The automatic detection machine distinguishes each filled bottle from non-quality bottles by sensing information such as the height and volume of the bottle opening. Thus one avoids the advantage of leakage and error of manual inspection, and further improves the accuracy and stability of quality control. In the case of faulty beverage bottles failing, the automatic sorting machine can handle abnormal bottles online or offline.

IV. Data-based recording of production process

In addition to visual management, the intelligent bottle production line can automatically record all data through the computer system, providing a reliable data-based basis for the quality management of pharmaceutical packaging. These data include information on temperature, humidity, pressure, process parameters, etc. during the production process. By analyzing these data, enterprises can find potential problems in the production process and make timely adjustments and improvements to ensure the stability of drug packaging quality.

In conclusion, in terms of pharmaceutical packaging quality management, the intelligent bottle production line has many advantages such as convenience, automation, high precision and visual management. In actual production, companies can ensure the quality of drug packaging by adopting intelligent bottle packaging production line, and at the same time, reduce the burden and effort of manual operation.

Choosing pharmapack has the following advantages:

1、One-stop service system:

Provide digital management and production solutions for every customer.

2、Superb technical advantages:

With nearly 300 patented technologies and industry-leading servo control technology, we are able to independently develop equipment and manufacturing industry-related software application systems, etc. according to market demand.

3、Digital cloud platform:

Digital cloud platform covering the whole life cycle of the equipment, to achieve digital production, marketing, operation and maintenance digitalization.

4、Customized exclusive service:

Pharmapack provide customized turnkey packaging solutions from the user's point of view. With our profound professional knowledge and rich experience in equipment installation, we create personalized solutions for our customers based on the data and needs provided by them. If you are considering purchasing a packaging machine, we will always be your reliable choice. Feel free to contact us at any time.