Improve production efficiency, pppharmapack Cartoner machine takes you to create greater value!

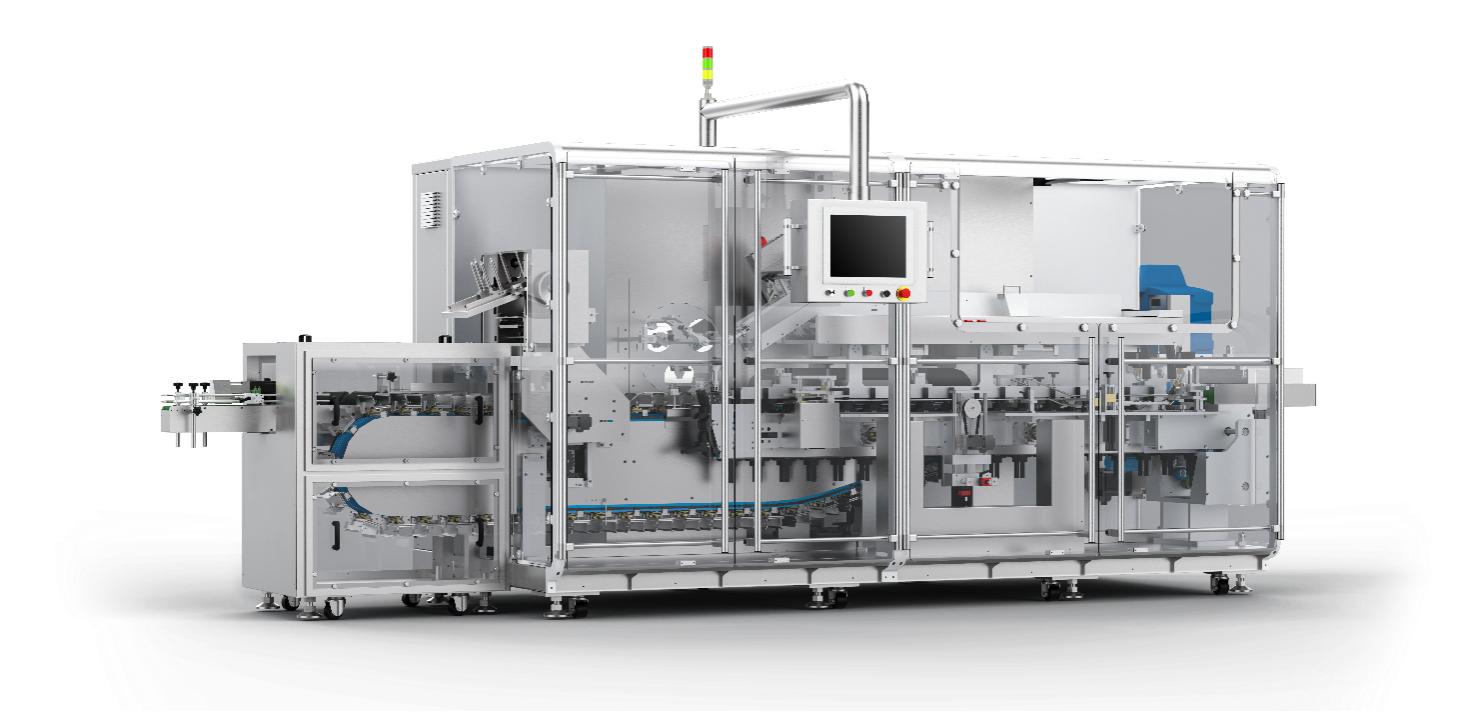

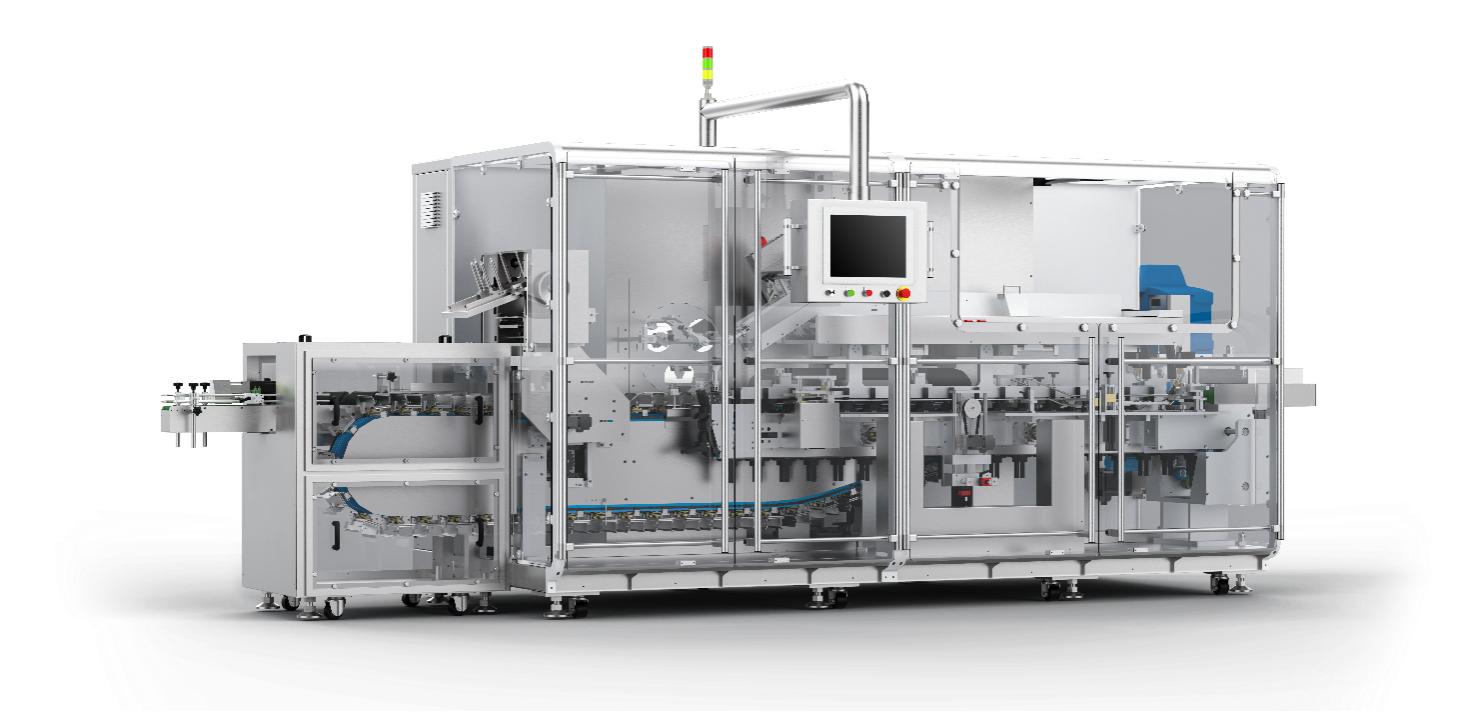

Introduction to ALFBC-25 Continuous Horizontal Cartoning Machine:

The ALFBC-25 Continuous Cartoner is an automatic carton packaging and sealing machine for bottles, blisters, trays, sticks, etc., widely used in food, pharmaceutical and cosmetics industries. It is typically used together with paper folding machine to put manual and product in the carton. The continuous horizontal Cartoner machine ALFBC-25 operates at a maximum speed of 250 boxes/minute. The paper box specifications are 30~70mm in length, 30~70mm in width, 78~140mm in height, and the maximum specification in the manual is 200mm × 320mm minimum 90mm × 100mm, the overall size of the packaging machine is 5500mm (L) × 2400mm(W) × 2200mm (H), with a total weight of approximately 3800kg.

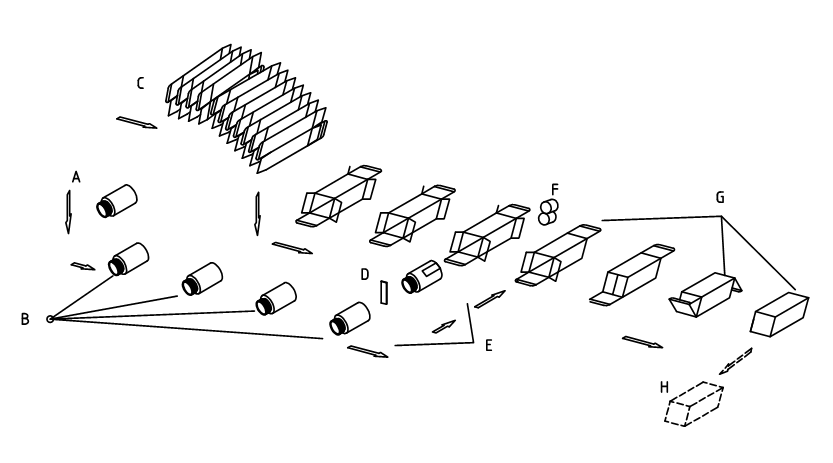

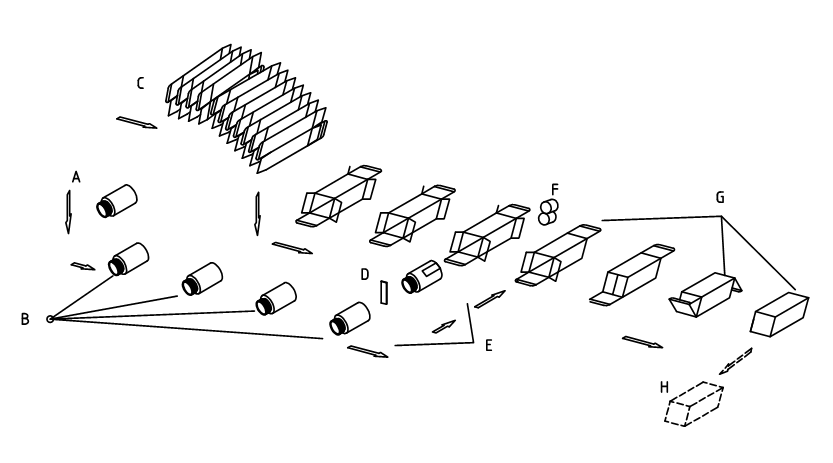

working principle:

There are three feeding gateways for manuals, bottles and cartons. Its working principle can be divided into the following four steps: carton placement, carton opening-up, filling and carton sealing. The suction cup sucks a carton from the hopper, and put it onto the conveyor. Carton is fixed on the conveyor and it will be opened by a push plate. After being filled, carton moves to the next step for tuck-in and cap closing.

Features

(1) Unique box structure design. Drive and auxiliary drive parts are all installed in the box cabinet to avoid paper scraps and material fragments falling into the drive mechanism. The equipment is running safely and hygienically, easy maintenance and servicing.

(2) Feeding belt and carton delivery belt adopt PU synchronous belt with metal rope, with low noise and smooth running.

(3) Box suction and box pre-opening are driven by independent servo motors, with flexible adjustment in horizontal and vertical directions.

(4) The cartoning part adopts mechanical synchronous pusher to achieve reciprocating cartoning while moving synchronously in the feeding conveyor belt, enhancing the cartoning speed and stability.

(5) The sealing part adopts a specific linkage curve (approximate ellipse) movement to complete the reciprocating sealing action in the movement.

(6) Chain and synchronous belt drive the conveyor to complete a series of bottle feeding, carton conveying, carton sealing, printing and outfeeding. Mechanical synchronization, no need to adjust the machine frequently.

(7) With digital display for adjustment when replacing products, easy record and zero errors.

(8) The feeding belt, carton feeding belt and sealing mechanism are installed with hanging method, easy to clean and maintain.

(9) With motor overload protection to ensure the safety of operation.

(10) With manual adjustment and electrical jog mode to facilitate equipment debugging.

(11) With sensor to detect incoming material. When there is material coming, machine will place it into the carton; when there is nothing coming, machine will run empty, reducing the number of equipment starts and stops.

(12) PLC controlled. English HMI touch screen, easy to learn and operate.

(13) Malfunction self-diagnosis, comprehensive and real-time monitoring, easy operation and maintenance.

For more information on pharmaceutical packaging machines, you can click on Pharmapack. We were founded in 2002 and are a pharmaceutical packaging machinery company headquartered in China. We have grown from a small enterprise to a professional company that provides a wide range of pharmaceutical packaging solutions. Decades of experience have given us mature experience and powerful technological update resources, enabling us to provide more advanced packaging and coding equipment to cater to the market.