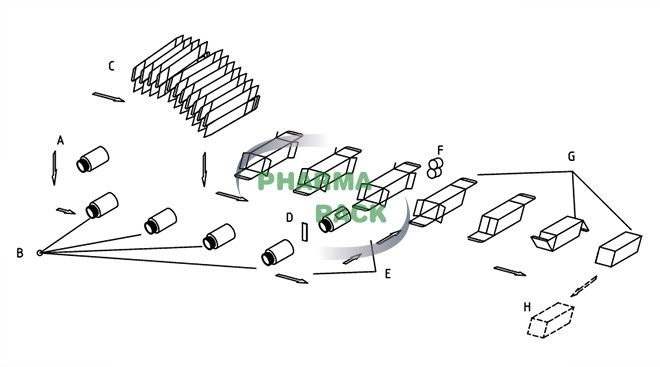

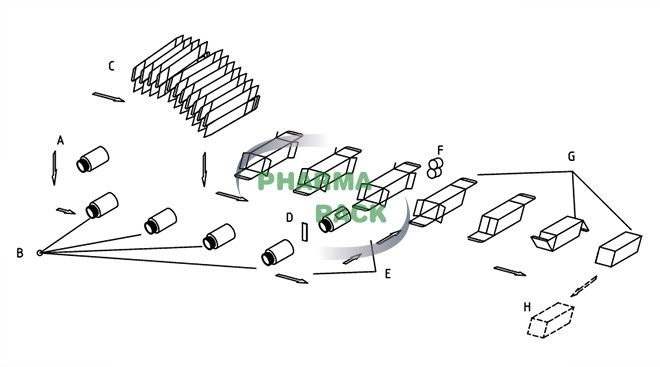

WORKING & PRINCIPLE

1. The product A is placed on the in-feeding conveyor B manually or automatically. After detection of product, the product coming sensor on the conveyor will send the signal for sucking out the carton from C and feeding onto the conveyor, pre-opening it while lift down.

2. Carton is put on the station while leaflet conveyed to the insertion point D. The leaflet will be inserted into the carton together with the product. Then the carton will be printed on the flap when it passes through F station.

3. The carton with inserted product and leaflet will be conveyed into gear-shape conveyor mechanically, and be tucked-into from the G point till finished. Then flap will be coded.

4. Defective product will be detected and rejected by point H which is set at the end of cartoners.

FEATURES

1.Separated cabinets design allows the driving parts and auxiliary parts built inside of cabinets, which prevent efficiently the paper and material chips from dropping into the driving system. Ensure sanitary, safety and easy maintenance.

2.Our products in-feeding conveyor and cartons conveyor, made up of alloy chains, carry products and cartons, low noise and stable running.

3.Carton sucking and pre-opening system adopts separated servo motors, which is easy to adjust direction of horizontal and vertical.

4.Insertion adopts mechanical pushers, which allows to continuously complete cartooning during product in-feeding conveyors running and ensures high speed and stability.

5.Adopt special ellipse similar coupler-point curve movement for flapping.

6.Products in-feeding, folded cartons loading, carton opening, flapping, indexing, coding, cartons out-feeding parts are driven by one motor, and adopt chain and synchronous belts driving system so as to both make sure mechanical synchronization and long-term running without any modification.

7.Adjustment system with digital indicator makes easy change-over and minimizes errors.

8.Suspended mounting for product in-feeding conveyors, synchronous belts, magazine and flapping mechanism, easy for cleaning and maintenance.

9.Overload protection equipped in main motor for equipment safety

10.To be convenient for commission, manual adjustment and inching function are equipped.

11.In-feeding detection sensor sends out signal that cartons and leaflets should be out. When products are detected. Otherwise, the equipment will idle to decrease stop times.

12.PLC and HMI are good for first learner. Trouble-shooting function and real-time monitoring system are good for easy operation and maintena.