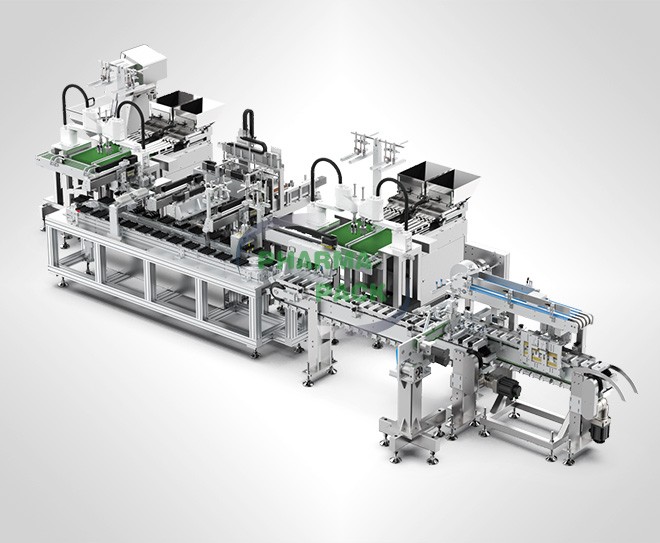

LFC-08CD Diagnostic Cassette Packing Machine

This machine is to assembly the diagnostic cassette and put the cassette & desiccant into a bag automatically. This machine consists of a few stations:

1. Cassette bottom cover sorting station

This station to sort the bottom cover of cassette orderly, photocells to check the cover position and direction. Those upside down cover will be picked up to the turning unit to turn it in the right position. Those reverse direction (back end in front) will be sucked by the vacuum cylinder and turn in the right direction. All the right cover will be delivered into the conveyor by twin-robots and to the diagnostic bar placing station.

2. Diagnostic bar cutting and dual-lane placing station;

The diagnostic bar cut from long bar (approx..25mm in length), the long bar stacked one by one and ready to be cut into small diagnostic bar. The camera will detect the small bar after cutting and ensure its quality, those defective will be rejected. The good diagnostic bars will be lifted and deliver to placing station.

3. Cassette top cover sorting station

This station to sort the top cover of cassette orderly, photocells to check the cover position and direction. Those upside-down cover will be picked up to the turning unit to turn it in the right position. Those reverse direction (back end in front) will be sucked by the vacuum cylinder and turn in the right direction. All the right cover will be delivered into the conveyor and to close the cassette.

4. Cassette assembling station

This station is to put the top cover onto the bottom with diagnostic bar, then press it to ensure the cassette close tightly.

5. Cassette transportation station

The finished cassette will be picked up and put onto the bucket conveyor, each bucket one cassette and move to desiccant and bag opening station.

6. Desiccant cutting and placing station

The Desiccant come by rolls, the desiccant will be cut into a piece then place to the bucket conveyor, each bucket conveyor one desiccant.

7. Bag opening station

The bag into the hopper to be sucked by the rotary arm and put to the bucket conveyor (different section of bucket conveyor for cassette and desiccant).The cylinder to suck the bag surface then two fingers to open the bag, this help to spare more space and make it easy to insert the cassette and desiccant.

8. Cassette & Desiccant inserting station

4 pushers to insert the cassette and desiccant into the bag. 4 pushers helps to increase the machine speed.

9. Bag sealing station

The bag sealing by heat seal with diamond cut on the surface, good sealing quality and good look.

Advantages

1. High speed

A. Four-lane conveyor design

B. Dual camera detection and twin robot mounting bottom cover

C. Dual diagnostic bar placing station;

D. Dual camera detection and twin robot mounting upper shell

Each station is seamlessly integrated through the servo control system, eliminating unnecessary delays of each process action to raise the speed and stability. The maximum speed can reach 5000 packs/hour;

2. Good stability

The diagnostic bars cut and checked by camera, those defective will be rejected. Those good ones will be lifted individually and delivered placing station. The dual-lane placing design helps to raise the speed.

3. Control system

Inovated motion controller is used to replace traditional PLC, with high positioning accuracy and more stable control; At the same time, it adopts EtherCAT bus protocol, which is anti-interference, fast transmission speed, neat and beautiful, and easy to use; The machine is convenient and intuitive.

4. Innovated heat sealing design

The sealing structure and bag leveling mechanism are designed with vertical and cross grains interlaced to better ensure the sealing performance and the flatness of the appearance.

5. Innovated bag opening and pushing station

Top and bottom sucking to open the bag, spare more space for pushing the antigen test kit into bag, make the bagging correctly and easily.

6. Ergonomic design

The outer frame of the whole machine adopts aluminum structure, which has a generous and beautiful appearance; The space is spacious, which is convenient for operation and maintenance.