Counter Machines: Revolutionizing the Pharmaceutical Packaging Industry

Counter machines have revolutionized the pharmaceutical packaging industry, making it more efficient and accurate. With the increasing demand for precision in medication packaging, these machines play a crucial role in ensuring the safety and effectiveness of pharmaceutical products. In this article, we will explore the significance of Counter machines, their impact on the Pharmapack industry, and the benefits they bring to both manufacturers and consumers.

The Importance of Counter Machines in Pharmapack:

Counter machines are designed to accurately count and package pharmaceutical products, such as tablets, capsules, and pills. They utilize advanced technology to automate the Counter process, eliminating human error and manual Counter. This not only saves time but also ensures the precise quantities of medications are dispensed. In the Pharmapack industry, where accuracy is paramount, Counter machines have become an indispensable tool.

Counter machines enable pharmaceutical manufacturers to achieve new levels of efficiency and accuracy in the packaging process. And play a vital role in maintaining high standards of quality control in the pharmaceutical packaging industry. The accuracy and efficiency that a pellet counter brings improves customer satisfaction, and investing in a Counter machine can lead to long-term cost savings for pharmaceutical manufacturers.

Pharmapack Counter machine is suitable for a variety of pharmaceutical packaging, let me share with you a few well-received machines:

1、ALFM-32C IN-MOTION MODULAR COUNTER

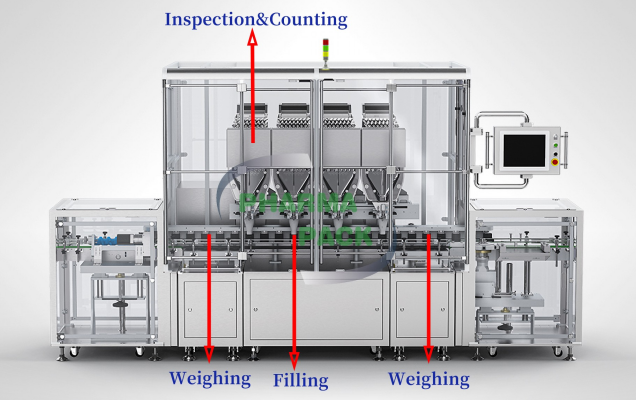

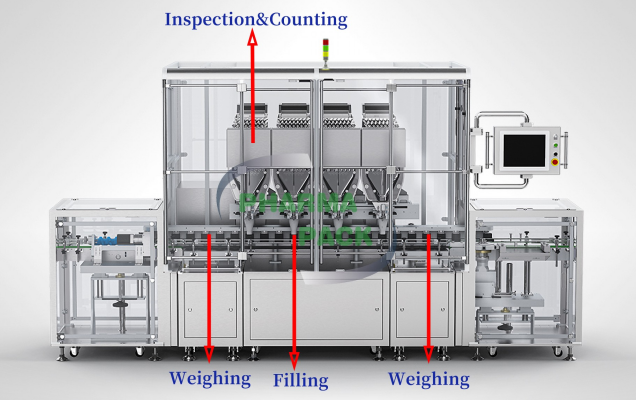

It integrates Counting, inspection, filling and weighing functions into one machine, to ensure the Counter accuracy and save space.

HIGHLIGHTS:

·Modular design, full servo-control

·Multifunction machine for inspection, Counter, bottle filling and weighing

·Exceptional 100% visual inspection of tablets, capsules & softgels.

2、LF-16 Tablet/Capsule Counter

The tablet Counter machine for pharmacy PP-16 is a reliable, high-performance automatic Counter machine, designed in conformance with current and proposed GMPs. Having a small footprint, they are effective in maintaining the integrity of a cleanroom environment. Few change parts are needed for different container sizes (only the nozzle). All product contact parts of the automatic Counter machines are made of type 316 stainless steel. And all contact parts can be easily disassembled for cleaning.

3、PP-12LC Follow-up modular granulator

PP-12LC is composed of 4 groups of single modules, continuous screw servo feeding system, servo system, rejecting star wheel servo system and so On.Through the servo system to ensure the complete synchronization of the motion unit, so as to ensure continuous 4 assembly bottle work, faster, more accurate, more stable work.

PP-12LC automatic modular Counter machine is manufactured using advanced Technology.The machine is made of high quality stainless steel, The appearance is exquisite, the mechanism is simple, the shape is beautiful, the maintenance is convenient.It can be widely used in the pharmaceutical industry of solid formulations of the Counter bottles, such as pills, sugar-coated tablets, tablets, soft /hard capsules and other shaped tablets.

Conclusion:

Counter machines have revolutionized the Pharmapack industry by making the packaging process more efficient, accurate, and cost-effective. With their advanced technology and ability to automate the Counter process, these machines have become an essential tool for pharmaceutical manufacturers. By ensuring precise dosages, enhancing quality control, and improving customer satisfaction, Counter machines have become a vital component in the production of pharmaceutical products. As the demand for precision and safety continues to grow, Counter machines will undoubtedly play a more significant role in shaping the future of the Pharmapack industry.