Features of PHARMAPACK Track&Trace System:

● Serialization, weight checking, coding, and Tamper-Evident labels for your product safety;

● An All-in-one camera inspection system can effectively reject defective products on the line;

● Track and trace product and its package (bottle, box, case, bundle, tray, etc.);

● Apply a unique identification code to each product, to trace its track.

a.Quality tracing management, this helps you quickly trace the source and flow if any problem;

b.Storage tracking management can improve your productivity and data accuracy;

c.Circulation tracking management can quickly implement pre-warning, and find out product location;

d.Marketing tracking management helps to trace the after-sale feedback;

● Comply with FDA 21 CFR Part 11 and realize data real-time synchronization;

● Timely and accurately save all information, then generate data chain for circulation tracking and tracing;

● Effectively prevent counterfeit medicine from entering the market and ensure the quality of medicines.

Solution

We know that every business is different. That’s why we provide a variety of custom packaging equipment that meets the unique needs of our clients.

Industry Application

Product: Trace&Trace System

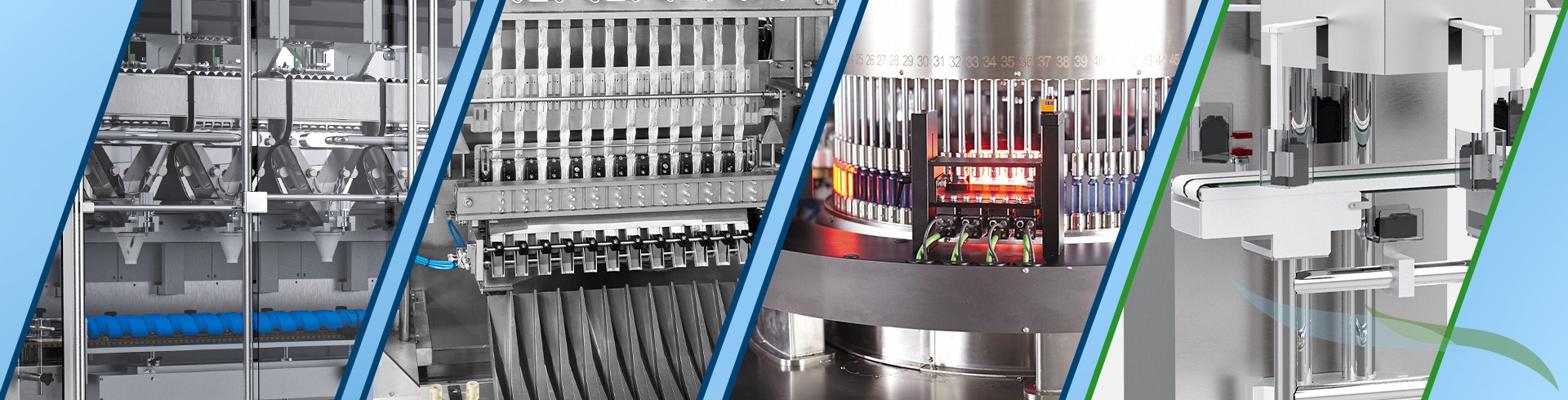

Function: PHARMAPACK Track and Trace System for Bottle Packaging Lines consist of turntable, vertical round bottle labeler,360°all-round inspection for bottles and vials, case packer(case forming & sealing).

How Pharmapack Bottle Packaging Lines Can Help Your Production

This new track and trace system can effectively achieve the process of serializing, labeling, detecting, case forming & sealing at high-speed, whole line speed up to 200 bottles/min. The line uses servo control and a high-precision & speed camera. Widely used in pharmaceutical, healthcare, food, and confectionery industries.

Customized Services

Pharmapack provides turnkey packaging solutions tailored to its customers. Pharmapack offers individual solutions based on the data and needs provided by different customers.

·Professional pre-sales and after-sales service center in Asia, Europe, and North America.

·Solutions for design aspects, commissioning, maintenance, or upgrades.

·Dedicated 24-hour online customer service group

Cases

At present, Pharmapack’s new track and trace system has been exported to more than 30 countries and regions around the world. We have successfully provided line installations for many well-known companies.

International:

Such as Pfizer, GSK, Johnson & Johnson, Abbott, Sanofi, AstraZeneca, Baxter, Mars, Wrigley, Perfetti, L'Oreal, AVON.

Domestic:

TongRenTang, Salubris, Jilin AoDong, North China Pharmaceutical Company, Harbin Pharmaceutical Group Holding Co., Ltd.

Yunnan Baiyao Group Co., Ltd, Guangzhou Pharmaceuticals. The Yangtse River, Tasly Pharma, Infinitus, BY HEALTH, etc.

Why Choose Pharmapack Machine

Experienced R&D Group PharmaPack congregates advanced technology in the world to supply the most advanced and guaranteed technical support for our customers. | One-stop Service System Pharmapack can supply the most perfect "turn-key" packaging solutions for every customer.

|

Industry-leading Technology New servo control with self-detection to replace the old cylinder, the flapper free of dust effect, more stable, longer life-span, lower maintenance cost. | Excellent Quality Control Tested by internationally certified companies, Pharmapack equipment has passed the evaluation of CE, UL Certify, CSA and complies with GAMP, FDA (CFR21), cGMP, and TGA standards. |