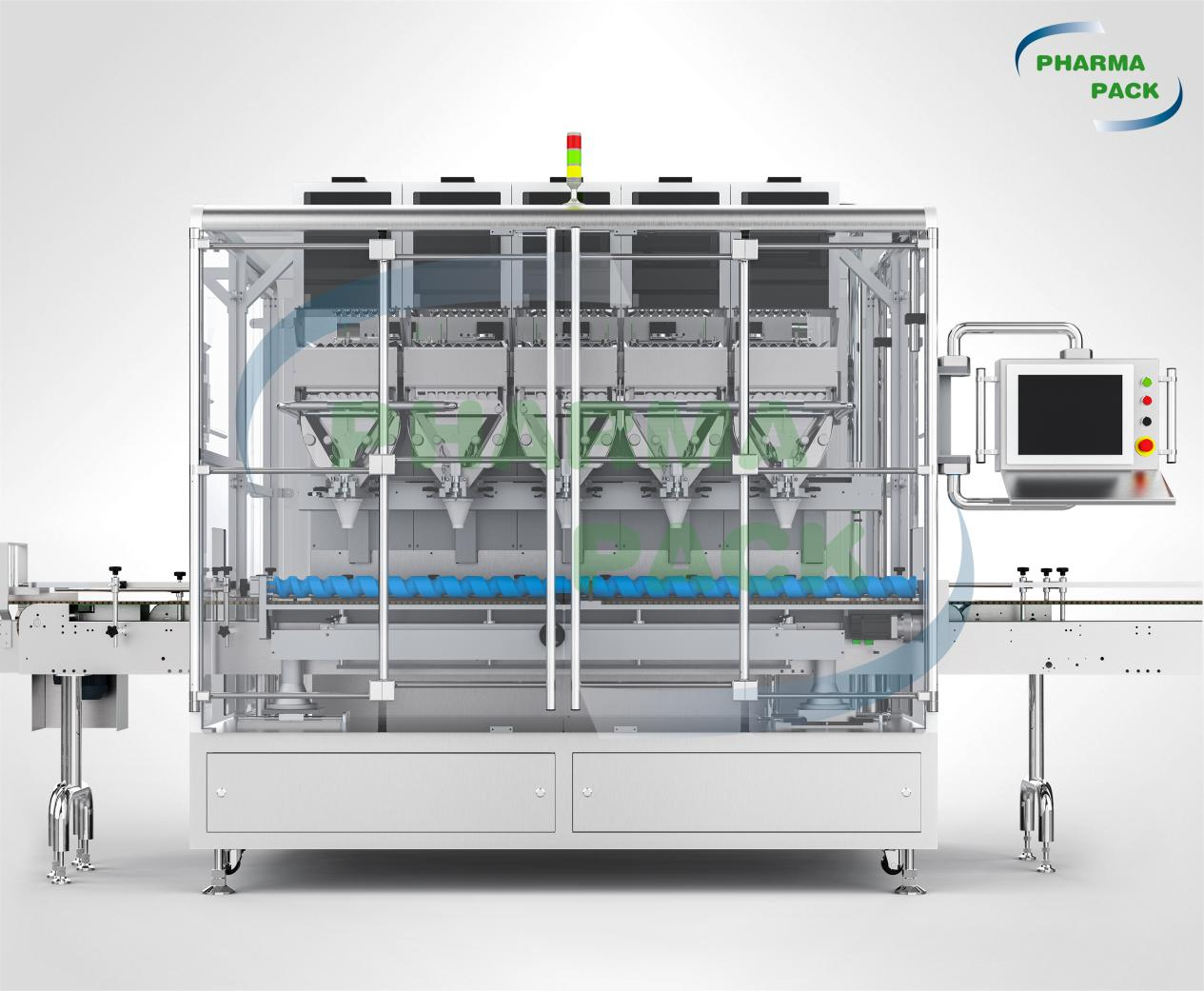

Efficient and accurate all-round solution: Pharmapack ALFM-40CWS tablet counting machine

The tablet counting machine, as a precision automation equipment, integrates the three functions of counting, canning and weighing, providing efficient and accurate solutions for pharmaceutical, health care products, food, pesticides, chemical and other industries. The main function of this equipment is to count, fill and weigh pills, tablets, soft and hard capsules and other solid preparations to ensure that the quantity and quality of the products during the production process are strictly controlled.

Overview of technical advantages of Pharmapack modular tablet counting machine ALFM-40CWS:

1. Servo vibration technology: high-frequency and low-amplitude vibration, increasing the particle counting speed by 50%, intelligent control, reducing noise, improving stability, fully sealed design, dust-proof, easy to clean and maintain.

2. Electronic counting technology: spherical infrared dynamic scanning electric eye, matrix electric eye layout with no dead ends, German MCU processor, high-speed electronic counting technology, automatic fault diagnosis, and storage of multiple sets of product parameters.

3. Modular design: Interchangeable modules, rapid production change and cleaning, full servo control, one-click production change, and follow-up canning to improve efficiency.

4. Servo control system: double material door design, precise grain counting, pre-counting function, visual feeding channel, easy cleaning and maintenance, high-precision synchronous bottling.

5. Double material door design: improve grain counting accuracy and speed, visual design, easy maintenance.

6. Online static weighing system: independently developed, high-precision weighing, re-weighing system ensures canning quality, and communicates with the tablet counting machine for automatic adjustment.

7. Fragment detection and rejection system (optional): miniaturized camera detection, automatic rejection of unqualified tablets, three-dimensional photography, AI algorithm, independent high-speed processing control panel, multi-angle detection and rejection.

Extreme production speed and strong drug adaptability

The ALFM-40CWS tablet counting machine can achieve an astonishing peak production speed of 30,000 grains/minute, fully meeting the enterprise's needs for efficient production. At the same time, the equipment also has a wide range of drug specification adaptability and can handle drugs with diameters ranging from Φ3 to Φ20mm and lengths ranging from 3 to 21mm. The diameter of medicine bottles ranges from Φ20 to Φ100mm, and the height ranges from 40 to 240mm, which can also be well adapted to this equipment.

Mature system supports:

It is worth mentioning that the operating system of the Pharmapack tablet counting machine ALFM-40CWS adopts the world's leading high-speed electronic chip counting technology and is supported by well-known manufacturers. It is based on advanced microcontroller (MCU) technology and is equipped with a dynamic graphical user interface in full Chinese, allowing all parameters to be easily set through the touch screen.

System features include:

1. Automatic fault diagnosis and real-time monitoring and alarm functions can store up to 100 sets of product parameters for quick recall when replacing products.

2. Flexible adaptability, can be easily adjusted to adapt to bottles of different heights, the entire process is operated through the touch screen, and the machine will automatically adjust to the appropriate height.

3. Enhanced security, the system supports three-level password permission settings to ensure operational security and data confidentiality.

With these advanced features and user-friendly design, our operating system not only improves production efficiency, but also ensures operational convenience and data security.

Conclusion:

If you are looking for a high-precision, high-quality pharmaceutical packaging machine, Pharmapack will be your ideal choice. Our entire line of equipment is manufactured in accordance with "international standards" and meets GMP, FDA and other certification requirements. As the setter of national standards for automatic counting and packaging lines, Pharmapack develops and applies network centralized control and online diagnostic functions that comply with the requirements of 21CFR Part11, leading the new development direction of the entire industry. Whether you have packaging equipment needs for pharmaceuticals, health care products, food or chemical industries, Pharmapack's pharmaceutical packaging machines can provide you with a full range of solutions.