automatic bottle labeling machine: An Industrial Tool to Improve Packaging Efficiency

automatic bottle labeling machines play a vital role in the packaging industry and are an integral part of the packaging machinery industry. As the crystallization of mechatronics technology, automatic bottle labeling machines not only provide strong technical support for the packaging industry, but also play a significant role in promoting the development of product appearance packaging. In many production fields such as alcohol, food, medicine, daily necessities, chemical products, etc., the impact of automatic bottle labeling machines is equally profound.

The use of automatic bottle labeling machines effectively frees workers from heavy and monotonous repetitive work. More importantly, it can significantly reduce the risk of workers being exposed to highly toxic, irritating, corrosive substances, as well as harmful working conditions such as low temperature, moisture, dust, etc., thus improving the working environment of workers and ensuring their health. In terms of productivity, the efficiency of automatic bottle labeling machines is usually more than ten times or even dozens of times higher than manual labeling. This improvement in efficiency plays a decisive role in upgrading product packaging styles and increasing packaging speed, allowing products to adapt to market demands more quickly and satisfy consumers' diverse choices.

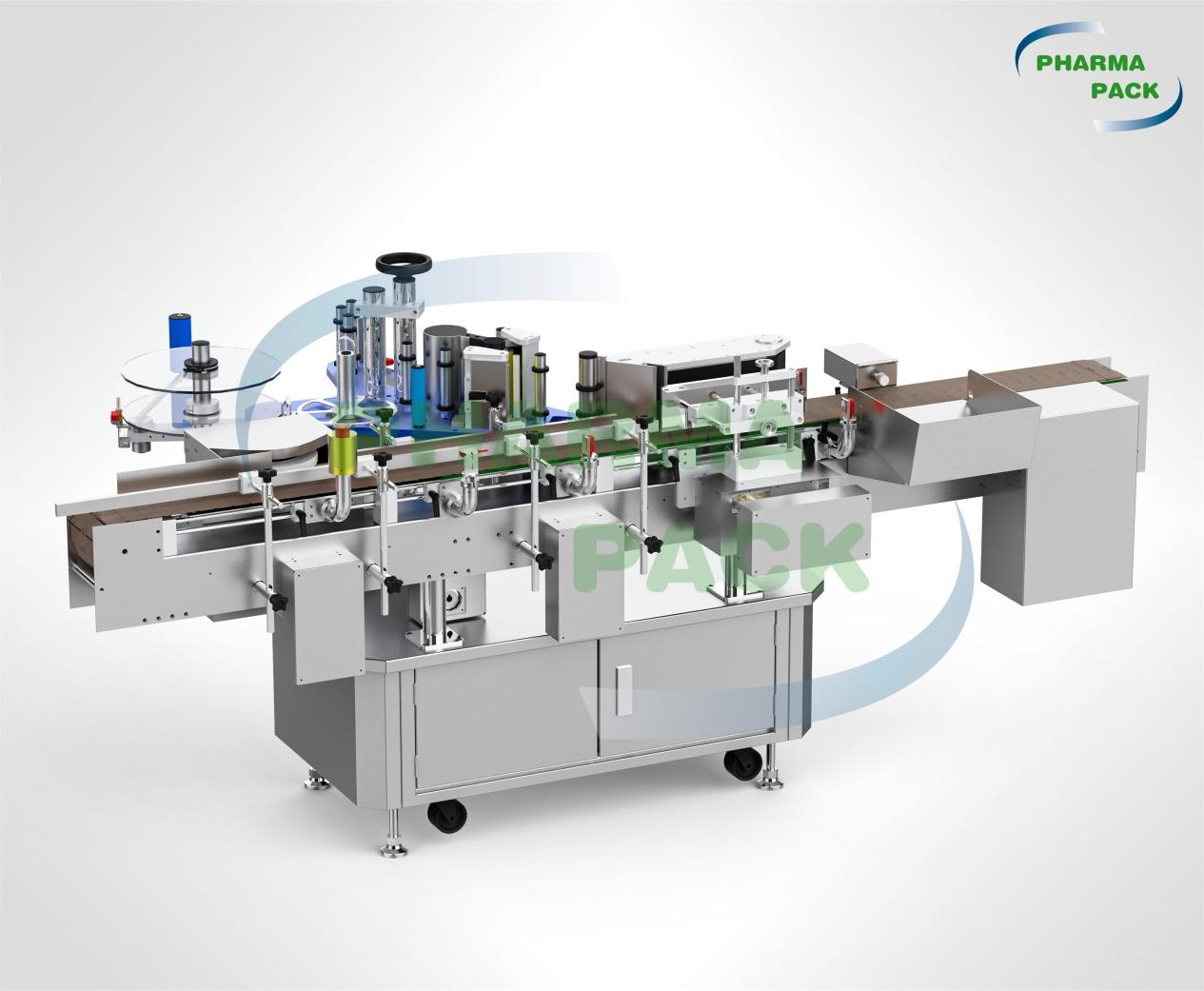

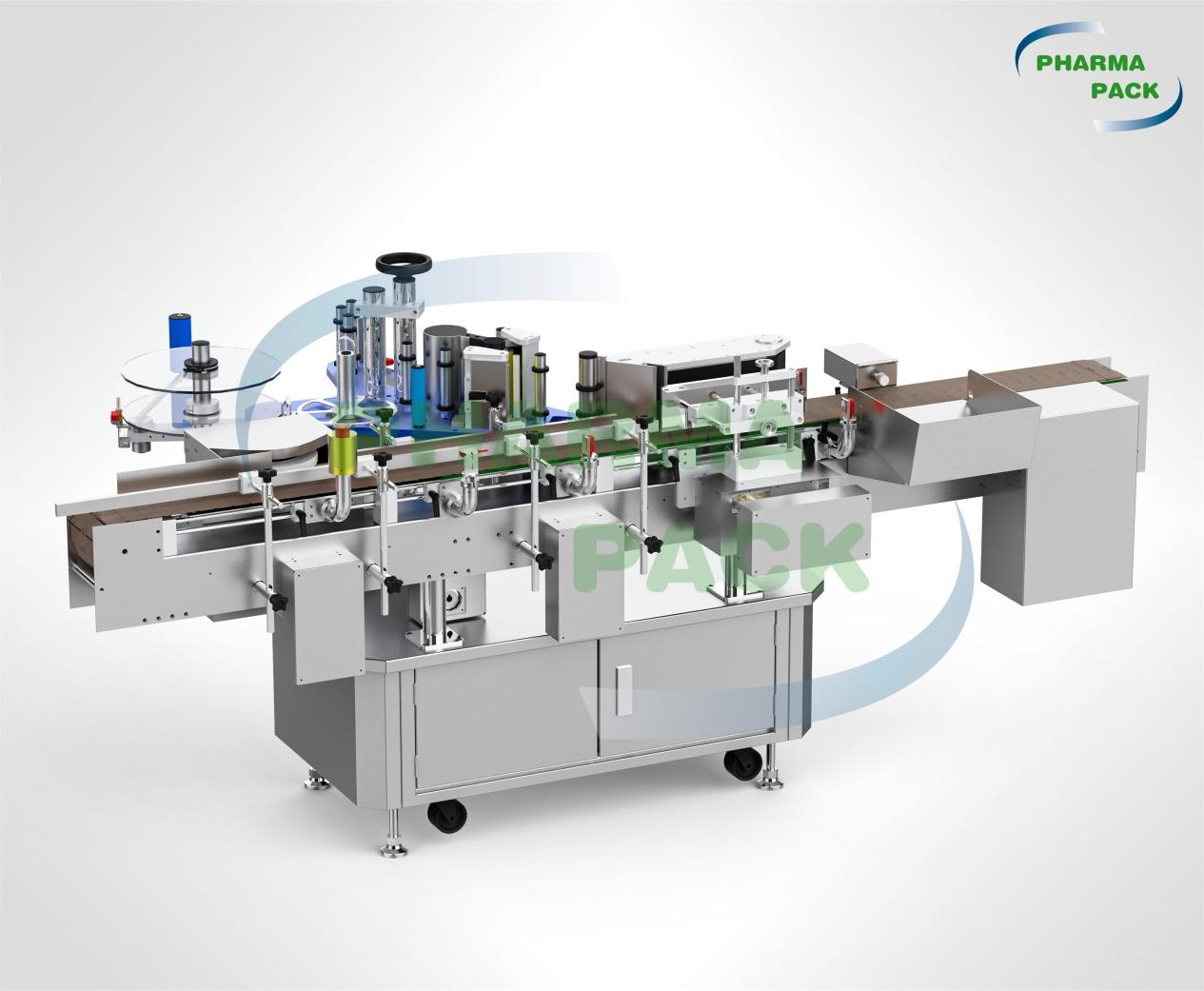

Recommended product: Pharmapack vertical round bottle labeling machine LFLB-1120

Pharmapack LFLB-1120 vertical round bottle labeling machine is a professional equipment for automatically pasting labels on the cylindrical surface of round bottles. It is especially suitable for the pharmaceutical industry and can realize rapid automatic labeling of various cylindrical containers such as vials, ampoules, oral liquid bottles, etc., effectively improving product labeling efficiency. A notable feature of this machine is that it can be used in conjunction with a hot stamping ribbon printer to print the logo content at a designated location on the label while labeling, which greatly improves production efficiency and the degree of personalization of the label.

Overview of the working principle of Pharmapack LFLB-1120:

1. When the labeling process begins, the bottles to be labeled are fed into the machine by the conveyor belt and sorted by the bottle sorting wheel to ensure that a certain distance is maintained between the bottles.

2. When the bottle reaches the position of the measuring object's electric eye, the measuring object's electric eye will immediately sense the presence of the bottle and quickly send a labeling signal to the label sender.

3. The bottles pass through the label output plate during transportation, and the labels are accurately attached to the bottles. At the same time, the bottle rolling belt rotates the bottle so that the label is tightly rolled on the circumferential surface of the bottle, while the bottom paper is rewinded.

4. When the label measuring sensor detects that the label has been completely attached to the bottle, it will send a signal to the label feeder to stop labeling, thereby completing the entire labeling process.

Features of round bottle labeling machine LFLB-1120

1. Intelligent control: The system adopts advanced microcomputer control technology, combined with intuitive touch screen menu operation, making parameter adjustment convenient and intuitive.

2. High-quality materials: All parts of the equipment, including base cabinets, conveyor belts, retaining rods and fasteners, are made of stainless steel and aluminum profiles, ensuring that the equipment will never rust and have zero pollution, fully complying with GMP environmental requirements.

3. Safety warning: The equipment has complete working status monitoring and fault warning functions, which not only improves the convenience of operation, but also enhances the safety of the maintenance process.

4. Intelligent management: The system has set up the total number of tags and remaining management functions, which can intelligently monitor the number of tags. When the total number of tags reaches the set value or the remaining number is lower than the set value, the system will automatically stop and alarm, which improves management. efficiency.

5. Reliable certification: All system control components have obtained international standardization certification and have undergone strict factory assessment tests to ensure the reliability and stability of various functions of the equipment.

Summarize:

Pharmapack focuses on "high-speed, high-precision" labeling machines and other automated packaging equipment, providing the best quality products and excellent services. If you have any needs for purchasing labeling equipment, you may wish to contact us on the official website of Pharmapack!