Choosing the Right Pharmapack Capping Machine for Your Pharmaceutical Needs

When selecting a pharmaceutical supplier, you may feel overwhelmed by the various capping machines. What is the difference between the Inline Capping Machine and the Inline Screw-On Capping Machine? Which products suit the Press-On Capping Machine and Rotary Capping Machine? Which one should you choose for your specific needs? In this article, we will analyze these four types of machines to help you customize the perfect capping machine for your products!

Exploring Different Types of Capping Machines

Inline Capping Machine

The Inline Capping Machine is widely used for various types and sizes of containers. It offers high automation and precision, enabling continuous capping operations on the production line. Inline Capping Machines are extensively used in the pharmaceutical industry to seal medication bottles, medical reagents, and various liquid products, ensuring proper sealing and hygiene.

Pharmapack's LFCL-15/15M Inline Cap Retorquer features advanced sensors and adjustment systems to position the caps, preventing leaks or looseness effectively and accurately. Furthermore, the machine has a HMI and operation control, making it simple to use and reducing training costs.

Inline Screw-On Capping Machine

The Inline Screw-On Capping Machine is crafted for screw-on caps. It utilizes rotational motion to attach screw-type caps onto bottles firmly. Using a Screw-On Capping Machine effectively prevents contamination and leakage, thereby extending the shelf life of your products. Standard containers that can benefit from screw-on caps include pharmaceutical bottles and prescription containers.

Pharmapack's LFCL-15F Inline Screw-On Capper is a compact machine that can easily integrate into your production line. It boasts a stable mechanical structure and an advanced control system, ensuring the machine's stability and reliability during extensive operation periods. The maximum screw-on speed can attain up to 150 bottles per minute. The capability to modify the cap rail allows for various cap types and product packaging, facilitating swift adjustments to your production line.

Press-On Capping Machine

The optimal choice is the Press-On Capping Machine when your product requires tightly sealed caps to ensure exceptional oxidation and corrosion resistance. It firmly attaches caps to containers using pressure and is adaptable to various bottleneck sizes. Additionally, the tamper-evident seal on medicine bottles ensures the safety and integrity of the product. When the seal is broken or tampered with, it leaves a visible mark or indication to alert the user.

Similarly, Pharmapack's LFCL-15FN Inline Screw-on/Press-on Capper can cater to your diverse requirements. You can specify the cap requirements for your medications and regulate the cap pressure and timing to achieve the best sealing quality. The pharmaceutical industry maintains strict standards for hygiene and compliance during the capping process, and the design of the LFCL-15FN Inline Screw-on/Press-on Capper adheres to current and proposed GMPs, ensuring worry-free and reliable production.

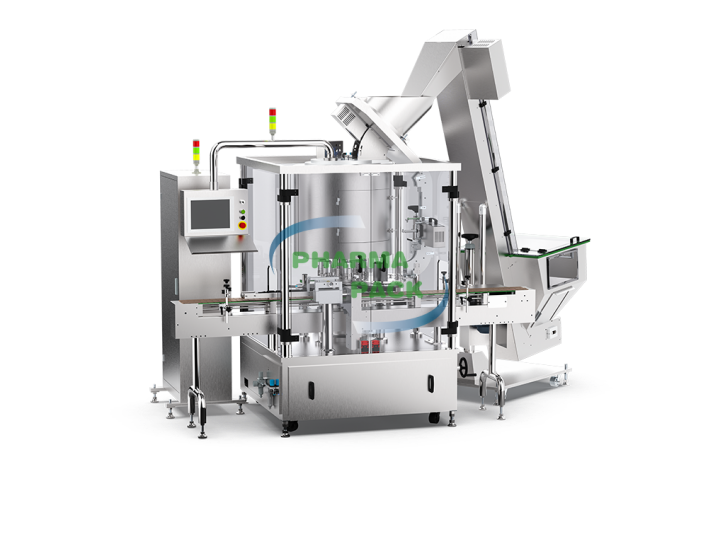

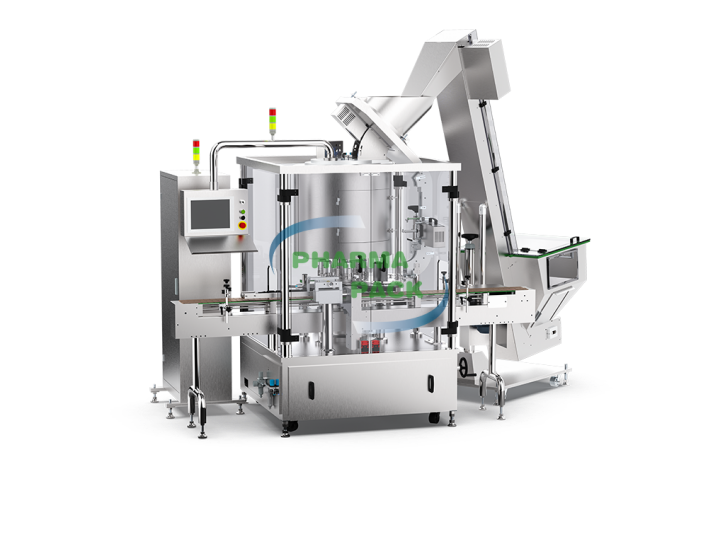

Rotary Capping Machine

Generally, a Rotary Capping Machine installs plastic or metal caps onto containers. Although it may appear complex, it often features high levels of automation. It is widely used in production lines requiring high-speed capping, such as bottled water production.

Pharmapack's LFCR-1506/2510/4016 Rotary Capper is specifically designed for medical containers. The machine incorporates PLC for industrial automation control, allowing it to start automatically in the presence of bottles and stop when bottles are absent. The main motor adopts a variable frequency drive motor from SEW Germany with power overload protection. This feature ensures stability and safety for motor components throughout production, making it a reliable guardian for your pharmaceutical manufacturing needs.

What Factors need to be considered before choosing a capping machine?

When making the decision to buy a capping machine, it's crucial to carefully consider and choose the most suitable one for your production line. What factors should you consider in detail when choosing a capping machine?

Production volume and speed

Determine your pharmaceutical production needs and the necessary operational speed. Different capping machines have various capacities and speed ranges, so it's essential to understand them in advance and choose one that aligns with your production requirements.

Capping specifications

Consider your pharmaceutical capping needs, including the type of caps, sealing strength, and stability. Ensure the capping machine accommodates all cap types and delivers the desired capping quality.

Space and layout constraints

Evaluate the space and layout constraints of your production line. The capping machine must fit seamlessly into your setup, so verify that its dimensions and layout match your constraints and needs.

Flexibility and customization

Consider the flexibility requirements of your production line. If you need to handle multiple cap types or bottle specifications, choosing a capping machine with adjustable features or customization possibilities would be a more suitable choice.

Conclusion

We introduced four common types of capping machines in the pharmaceutical industry. Please choose the ideal capping machine that best suits your product type and packaging needs. Alternatively, you can further discuss your specific requirements with suppliers to provide efficient capping solutions for your pharmaceutical production line. For more information, please click Pharmapack.

Related Articles:

Streamlining Packaging Efficiency: The Advantages of Pharmapack's Cartoner

Efficiency and Precision Combined: The Game-Changing Pharmapack Labeler

Maximizing Productivity with Pharmapack’s 360-degree AI Counting and Sorting Machine