A Comprehensive Guideline of PHARMAPACK's Track and Trace System for Bottle Packaging Lines

Implementing an effective track and trace system is vital for pharmaceutical companies to ensure product safety, quality, and regulatory compliance throughout the packaging process. Pharmapack provides advanced tracking and packaging solutions specifically tailored for bottle and carton packaging lines to meet the precise needs of the pharmaceutical industry. In this guide, we'll explore the key components of Pharmapack's track and trace system and how it enables precise, efficient, and compliant packaging operations.

Overview of the PHARMAPACK's Track and Trace System for Bottle Packaging Lines

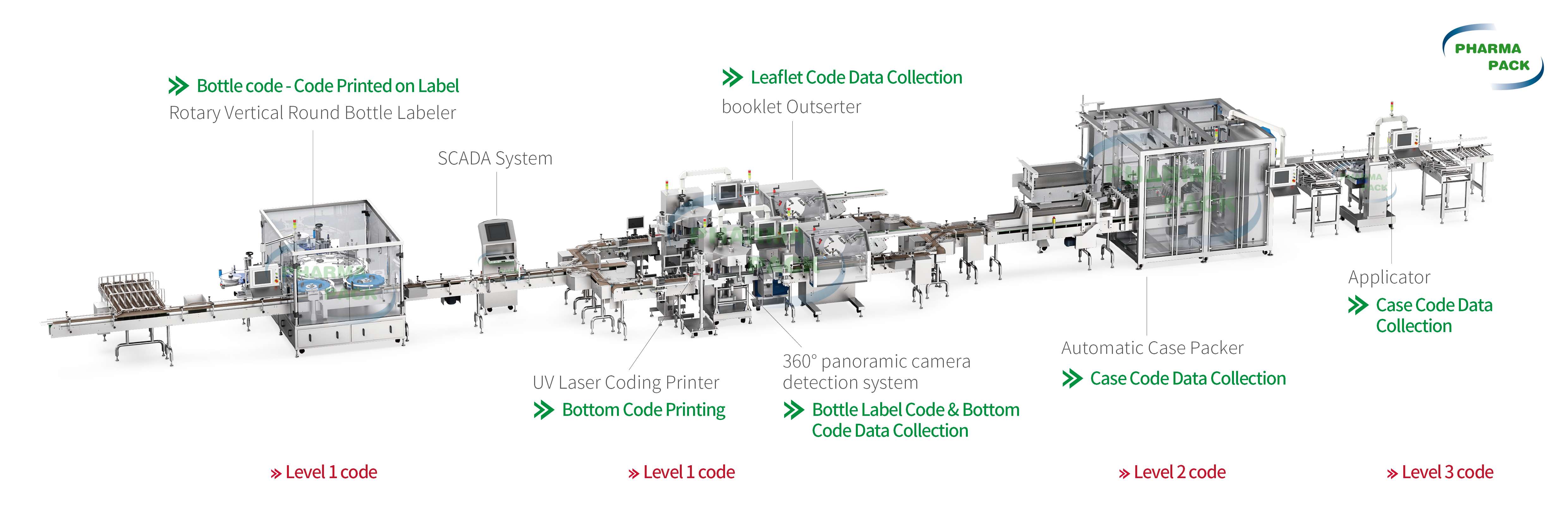

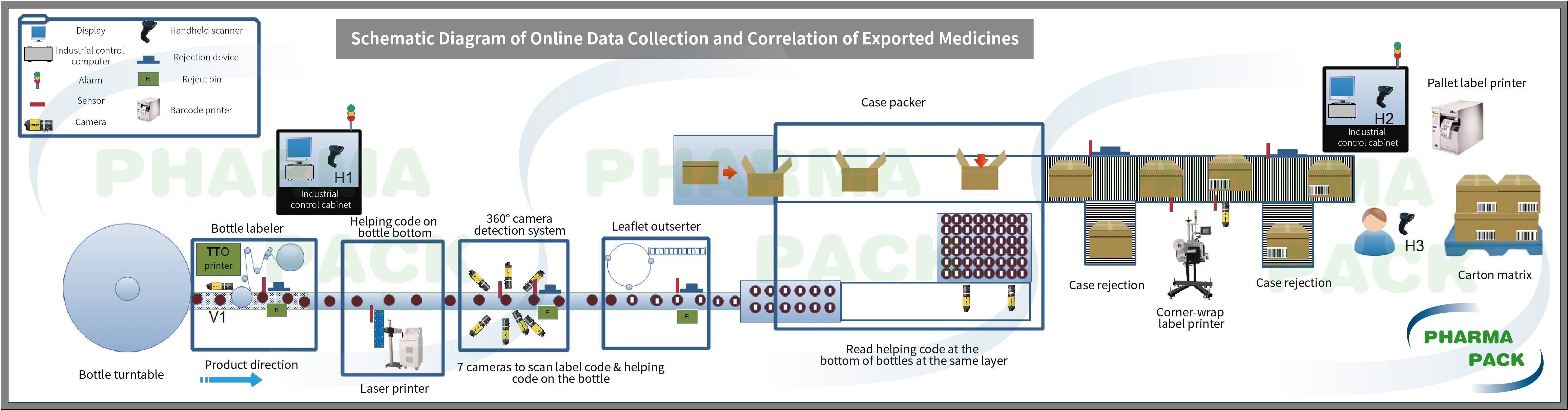

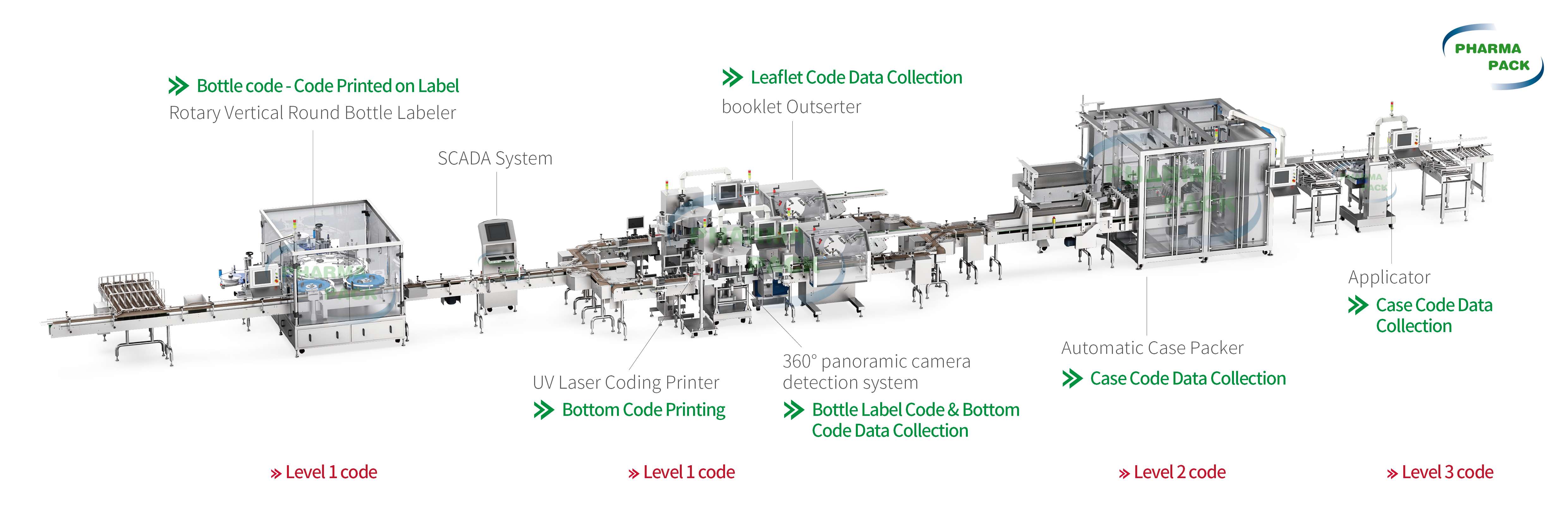

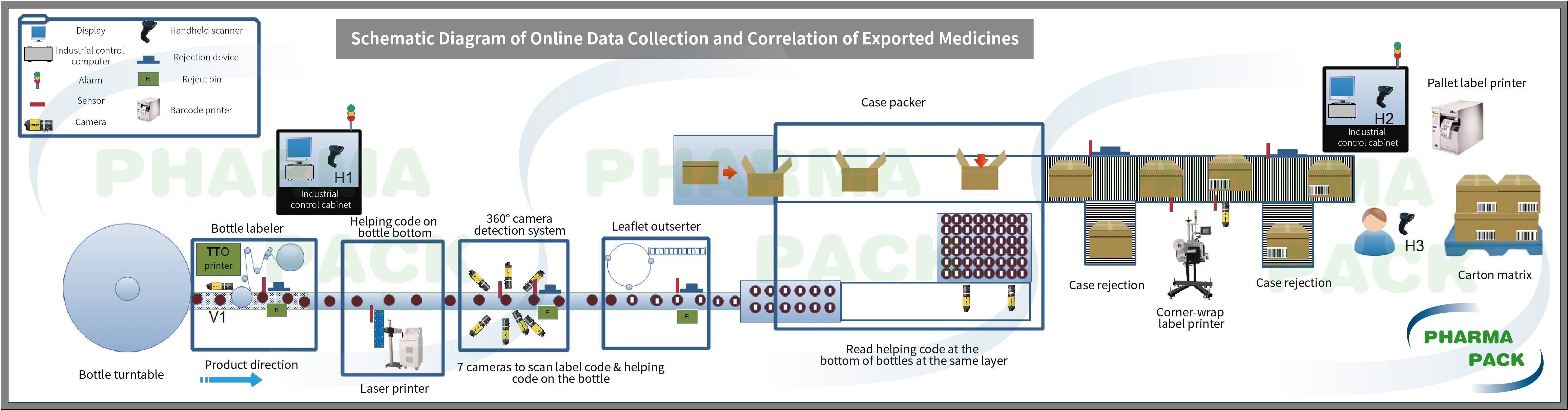

PHARMAPACK's Track and Trace System for Bottle Packaging Lines is a complex integration of components designed to simplify the serialization, labeling, inspection, and packaging process. Key components of the bottle packaging line include turntables, vertical round bottle labelers, 360°camera inspection systems for bottles and vials, and case machines for forming and sealing. The cohesive system operates at high speeds, with full line speeds up to 200 bottles per minute.

Here are some features of this track and trace system for bottle packaging that you should know:

1. Turntable for efficient bottle handling: The turntable serves as an initial stage to efficiently handle bottles and facilitate their movement on the smart packaging line.

2. Vertical round bottle labeler: This component ensures accurate labeling on each bottle with a unique identification code (called Level 1 code).

3. 360° camera detection system: This system inspects bottles and vials from all angles, capturing a 360° view. It generates a help code for the bottle cap, including all the booklets on the cap and the bottom of the bottle, creating what is called a Level 2 code.

4. Serialization with full traceability: Customers have the flexibility to combine corner pack labelers and pallet labeler printers to create Level 3 codes. This comprehensive coding system enables tracking from warehouse to logistics to retail stages.

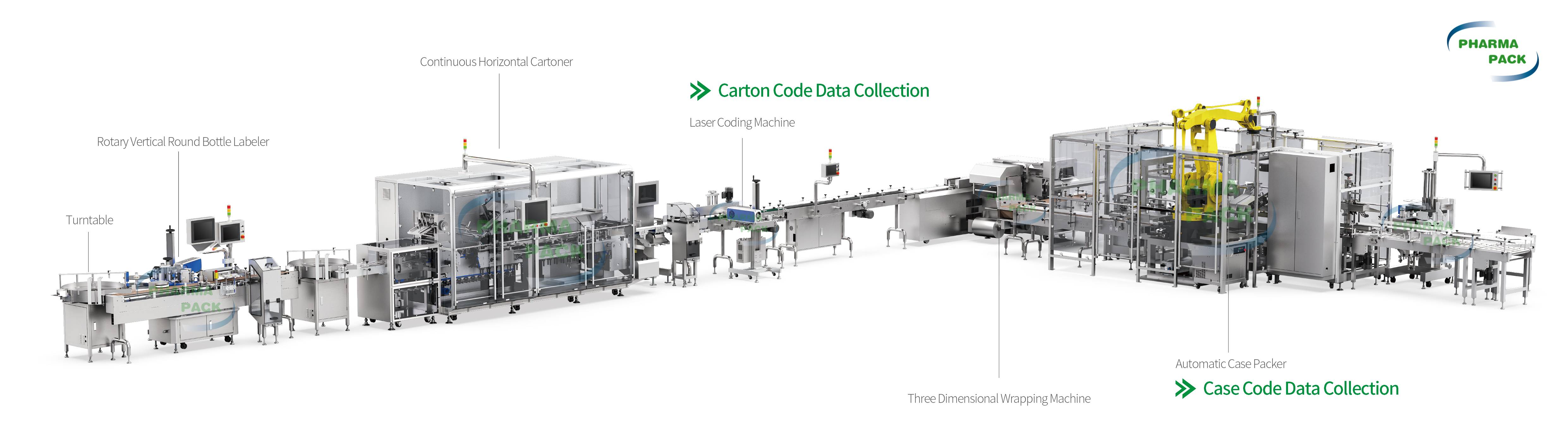

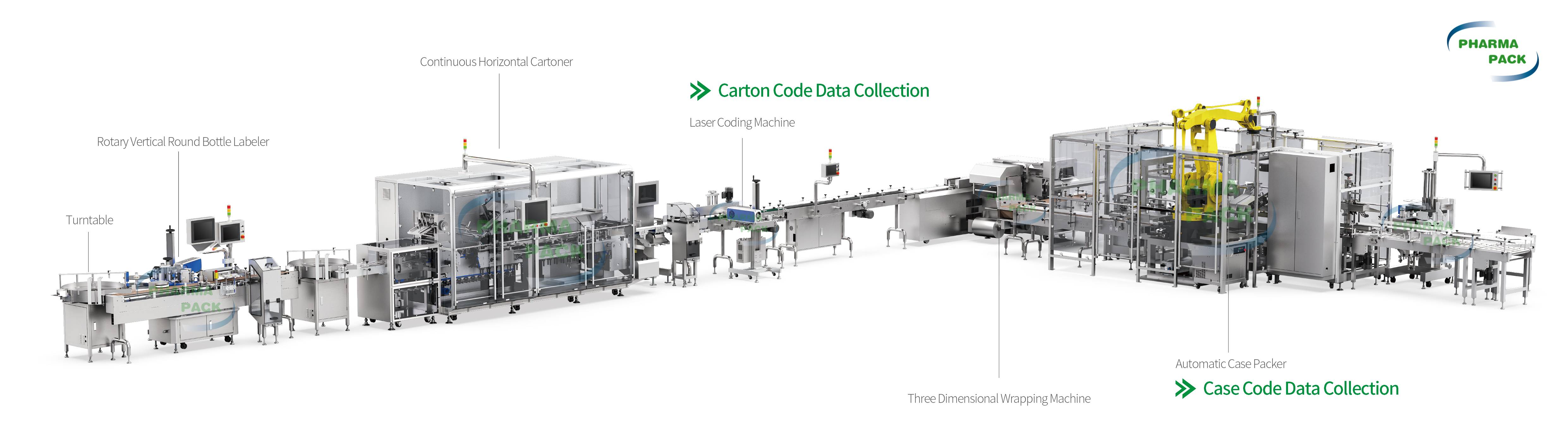

Overview of PHARMAPACK's Track and Trace System for Carton Packaging Lines

The application of Pharmapack's Track and Trace System for Carton Packaging Lines extends to carton packaging lines, providing serialization, check weighing, tamper-evident labeling, and semi-automatic aggregation. The complete line speed of up to 250 bottles/minute has proven its efficiency in a variety of pharmaceutical packaging scenarios.

Here are some features of this track and trace system for carton packaging that you should know:

1. Weight check accuracy: Adding a check weight ensures products meet precise weight specifications, helping with quality control and compliance.

2. Tamper-evident labeling: The system uses tamper-evident labels to protect medicines from potential tampering and to enhance safety measures.

3. Semi-automatic aggregation: The semi-automatic aggregation function is an effective tool for tracking products and contributes to the overall traceability of pharmaceuticals.

Functionality and Benefits in Enhancing Pharmaceutical Packaging Processes

PHARMAPACK's track and trace system ensures a coherent and efficient process from handling, labeling, inspection, and packaging. The system's automation minimizes the risk of errors, providing a reliable and consistent packaging solution.

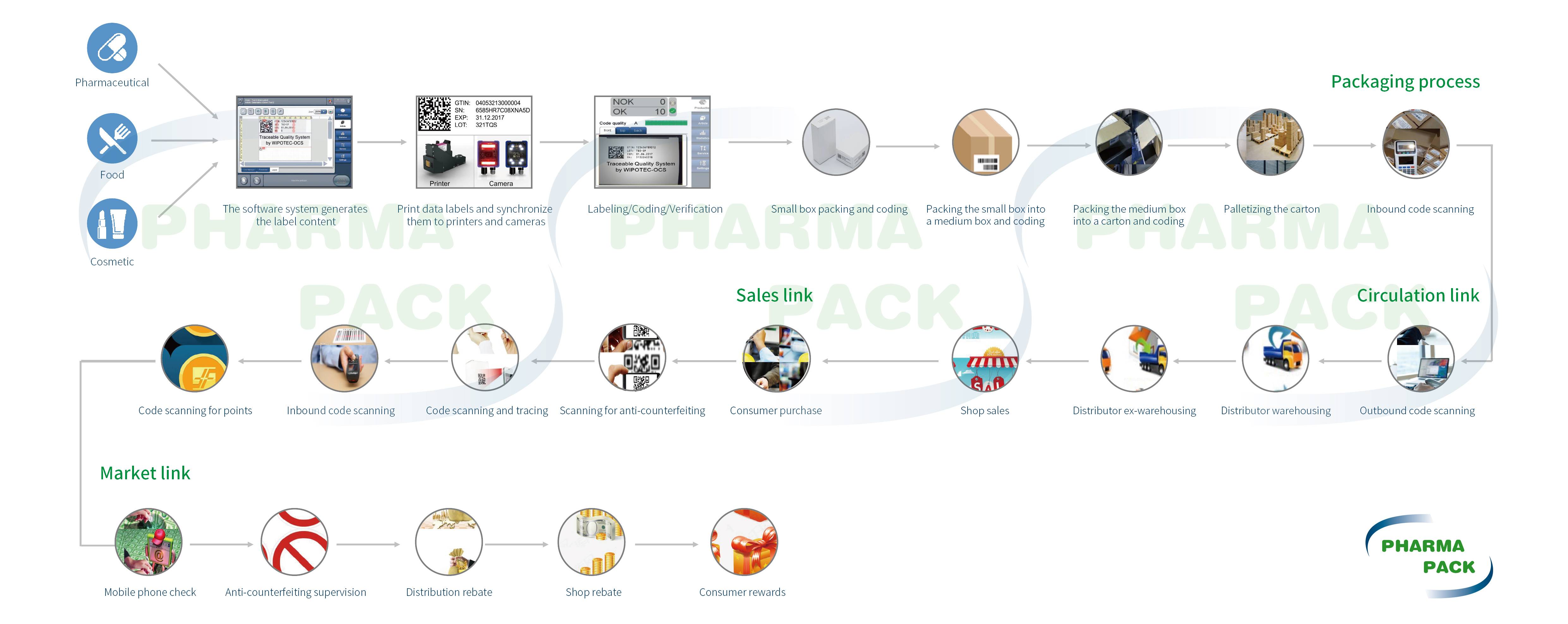

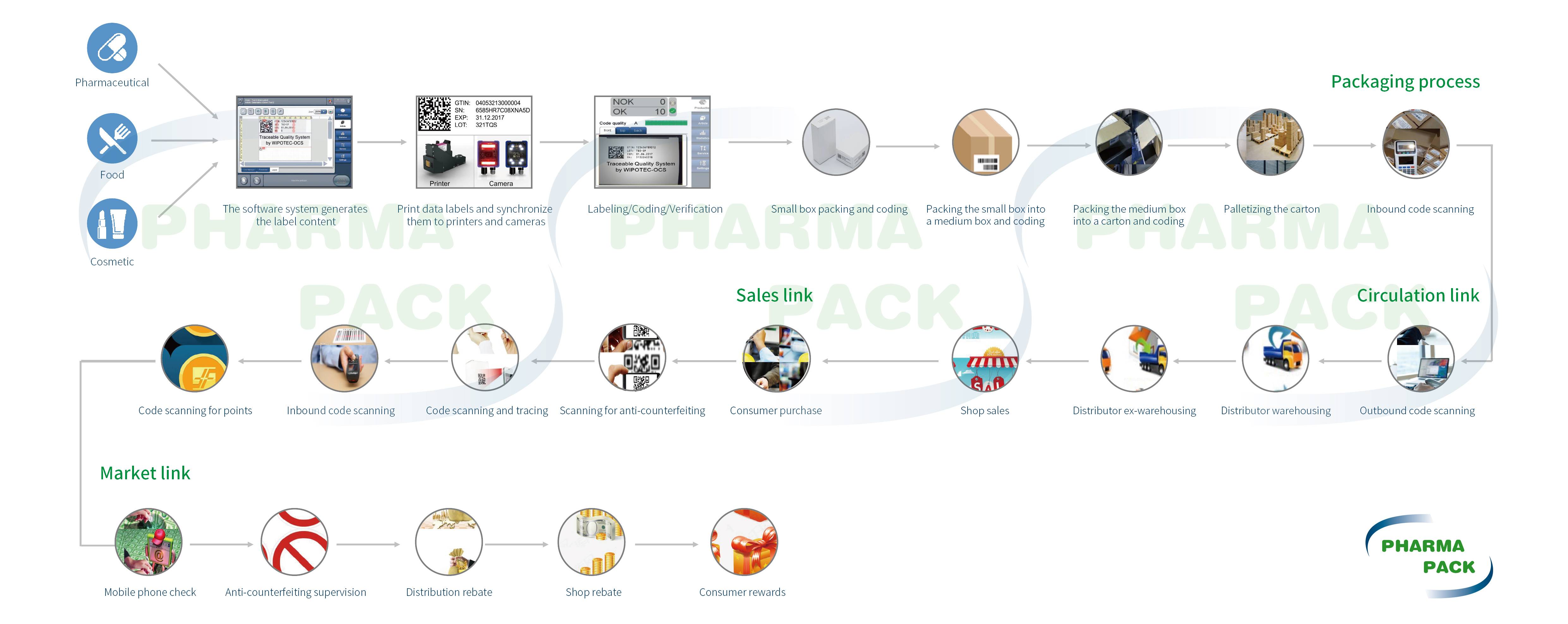

The core function of the system is to ensure the safety, compliance, and quality of pharmaceutical products. This track and trace system allows manufacturers to track each product from production to distribution, ensuring that every product purchased by consumers is safe. This enhances compliance with regulatory standards and helps maintain the highest quality throughout the product life cycle. This integrated system provides:

1) Enhanced product safety and integrity: The system's serialization and inspection capabilities help enhance product safety, ensuring that only defect-free and accurately labeled products enter the market.

2) Regulatory compliance and meeting industry standards: Meeting regulatory requirements is imperative in the pharmaceutical industry. PHARMAPACK's track and trace systems are designed to comply with industry standards, providing reliable solutions for regulatory compliance.

3) Improve the efficiency and speed of the packaging process: Automation can improve the efficiency and speed of the packaging process, reduce manual labor, and speed up the production cycle.

4) Versatility for various industries: Although tailor-made for the pharmaceutical industry, the system's versatility extends its applications to the healthcare, food, and confectionery industries, providing a flexible and adaptable solution.

5) Space-saving design for facilities with limited space: The system's thoughtful design takes into account the space constraints of the facility, providing a space-saving solution without compromising functionality.

By implementing a track and trace system on the packaging, pharmaceutical companies can digitally monitor the entire process of each product, from manufacturing to shipping. This prevents counterfeiting, diversion, and recalls while complying with safety regulations. The user-friendly system also integrates with existing production lines and IT infrastructure.

As regulatory requirements and quality standards continue to increase across the pharmaceutical supply chain, advanced track and trace systems are critical for end-to-end visibility, safety, and compliance. Contact PHARMAPACK today to learn how our bottle and carton line solutions can optimize your track and trace operations.

Related Articles:

An Inside Look at Pharmapack's Cutting-Edge Inspection Technology in the ALFIM-72

Unveiling Precision: The Automatic Leak Detection Machine LFIV-25

Pharmapack's New Product Lineup: Redefining Pharmaceutical Quality Control