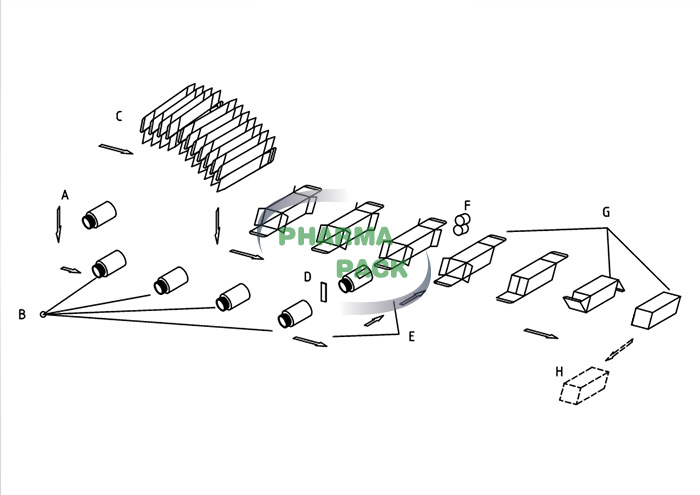

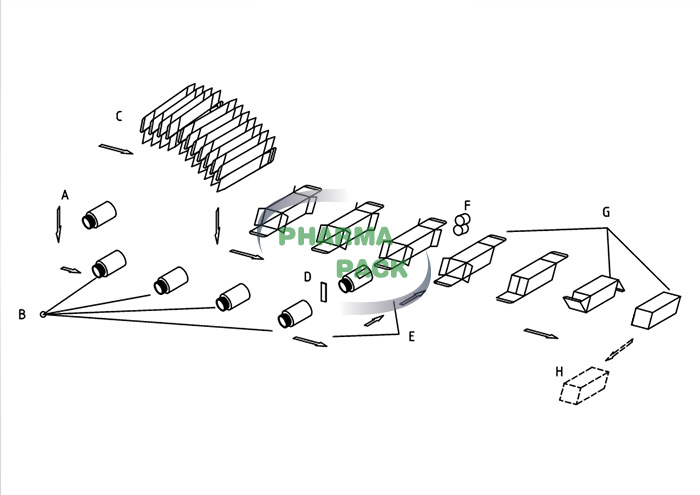

WORKING PRINCIPLE

1.The product A is placed on the in feed conveyor B manually or automatically.After detection of product,the product coming sensor on the conveyor will send the signal for sucking out the carton from C and feeding onto the conveyor ,pre-opening it while lift down.

2. Carton feed to the station while leaflet conveyed to the insert point D.The leaflet will be inserted into the carton with the product.Then the carton will be printed on the flap when it pass through F station.

3. The carton with inserted product and leaflet will be conveyed into gear-shape conveyor machanism, and be tucked-into from the G point till finished.

4. The end of cartoner is fixed rejection machanism H for detection and rejection of defective.

FEATURES

1.Differently tank-construct design to realize to fix the driving parts and auxiliary parts inside of tank, which prevent efficiently the paper and material chips droping into the driving machanism. Sanitary and safety, easy maintenance.

2.Product in feed conveyor and carton in feed conveyor adopt the timing PU conveyor (with medal thread) to convey the product and carton.Low noise, stable run.

3. Suck and pre-open carton system adopt unique servo motor, easy adjustment in direction of vertical and level.

4. Insertion adopts double servo motor, which realizes movement in vertical and horizantal to finish the insertion; high speed and stability.

5. Insertion adopt special link rod to make curve movement (ellipse similar) and finish the tuck-in repeatedly.

6. Bottle in-feed ,carton in-feed,carton suck out,carton tuck-in ,printing ,carton out feed etc are driven by same motor ,chain and timing belt are adopted ,timing machanism ,easy operation .

7. The adjustment machanism with digital indicator make change over easily .

8. In feed conveyor, carton in-feed belt, carton base conveying and all the carton tuck-in etc are adopted suspension, easy clean and maintenance.

9.Main motor with over load is to make equipment work safety.

10.Jog manually and electrically is to make easy operation.

11. Product inspecting system. No bottle, no carton suck-in and no leaflet.

12. PLC and HMI are adopted, easy study and easy operation .Trouble shooting self teaching and overoll in time monitor.